The CDI Flexible Furler can be used to both reef and furl your sail in any wind condition. CDI has simplified the design, thereby increasing the system's reliability while lowering the cost.

| System | Main Stay Length | Max Wire Size | Turnbuckle Size | Luff Dimensions | Drum Diameter |

|---|---|---|---|---|---|

| FF1 | 21' | 1/8" | 1/4" | 0.5 x 1.3" | 3.5" |

| FF2 | 29' | 3/16" | 1/4" - 5/16" | 0.6 x 1.4" | 4.0" |

| FF4 | 33' | 7/32" | 1/4" - 3/8" | 0.92 x 1.8" | 5.8" |

| FF6 | 39' | 1/4" | 5/16" - 7/16" | 0.92 x 1.8" | 5.8" |

| FF7.0 | 47' | 1/4" | 7/16" - 1/2" | 0.92 x 1.8" | 6.5" |

| FF9.0 | 53' | 5/16" | 1/2" | 1.2 x 2.2" | 6.5" |

| Features | American |

|---|---|---|

| Luff Deduct | 13.0 in | |

| Luff Tape | #6 | |

| Min Tack Height | 6.0 in | |

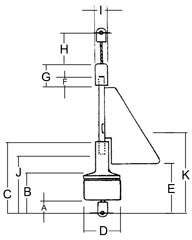

| A | 1.3 in | |

| B | 4.5 in | |

| C | 9.0 in | |

| D | 3.5 in | |

| E | 7.0 in | |

| F | 1.3 in | |

| G | 2.5 in | |

| H | 2.0 in | |

| I | 2.0 in | |

| J | 7.8 in | |

| K | 17.5 in |

Dimensons A-E depend on the length of the toggle at the bottom of the turnbuckle. Dimensions shown assume Merriman (now MacWhyte) turnbuckle.

Dimension H is approximate. The length required may be greater to provide adequate clearance for a Spinnaker halyard, or may be slightly shorter to accommodate a full hoist sail. Dimensons H is intended to provide adequate clearance to allow headstay adjustments without the furler binding at the top. Dimensons H is also necessary to provide clearance between the mast and the halyard top fitting.

Simplicity

Often, the simplest product is the best product. The Flexible Furler has one-eighth the number of parts of competitive systems and is the easiest to install, operate and maintain. Plus, the Flexible Furler is backed by an unequaled warranty.

A patented, one-piece, UV stabilized PVC luff extrusion. This luff extrusion is as stiff in torsion as a metal system, and yet can bend without kinking, unlike metal systems. There are no joints to fail and it is designed to be winched.

A built-in halyard, eliminating troublesome halyard swivels and halyard wrap, maximizing reliability whether offshore or close to home.

Reliable Furling

CDI's durable one-piece urethane furling drum and stainless steel drum cover keeps the furling line in place. You can accidentally drop your anchor onto the Flexible Furler drum and expect it to keep working!

Fail Safe Bearings

Because of the built-in halyard, our rugged bearings see only a fraction of the load carried by other systems. Smaller Flexible Furlers typically use a one-piece solid plastic bearing, though some sailors prefer ball bearings as a convenience option (like having power steering in a small car).

The FF9.0 and 9.0 come with ball bearings standard. We use 1/2" Torlon balls which roll over dirt easier and need less maintenance than the 1/4" balls you find in less rugged systems.

Easy Installation

Designed to be installed over your existing stay, cutting in half the installation time.

Low Maintenance

We recommend that you rinse your bearing with a hose every 5 years (a 5 minute procedure).That's it! And you don't have to drop your sail to rinse the bearing. ![]() CDI Flexible Furler FF9 Manual.pdf

CDI Flexible Furler FF9 Manual.pdf

Call us for technical support, customer service and product information (877) 240-VELA (8352)